How Preformed Thermoplastic Works and Bonds to Asphalt and Cement Surfaces

The purpose of this article is to explain how thermoplastic works and how it bonds to surfaces. By understanding how this product works it will help you in determining if thermoplastic will meet your needs and perform as expected. It will also help you to understand why the steps taken during installation are necessary.

By definition, thermoplastic is a plastic that when hot turns into a liquid and when cool hardens into a solid. It has a multitude of applications because of this characteristic. In general, the majority of preformed thermoplastics as well as regular thermoplastics are made up of Alkyd Resins, Polymers, Fillers, Glass Beads for reflectivity and Pigments for color. The main ingredient is the Alkyd Resin. The other ingredients add desirable characteristics to the product such as wear resistance, reflectivity and color.

For the most part, the bond that thermoplastic makes is a mechanical bond which simply means it grabs the surface and holds on much like a rock climber looks for crevices to grab while climbing. On certain surfaces an additional bond is achieved when the hot thermoplastic and the hot surface actually melt and mix together creating more of a cohesive bond. As stated before, the material becomes liquid when hot. When it is in this state it fills in every pore, crack and crevice of the surface that it is on. When it cools it is locked into place. In the sections below this will be covered in more detail.

PREMARK Preformed Thermoplastic

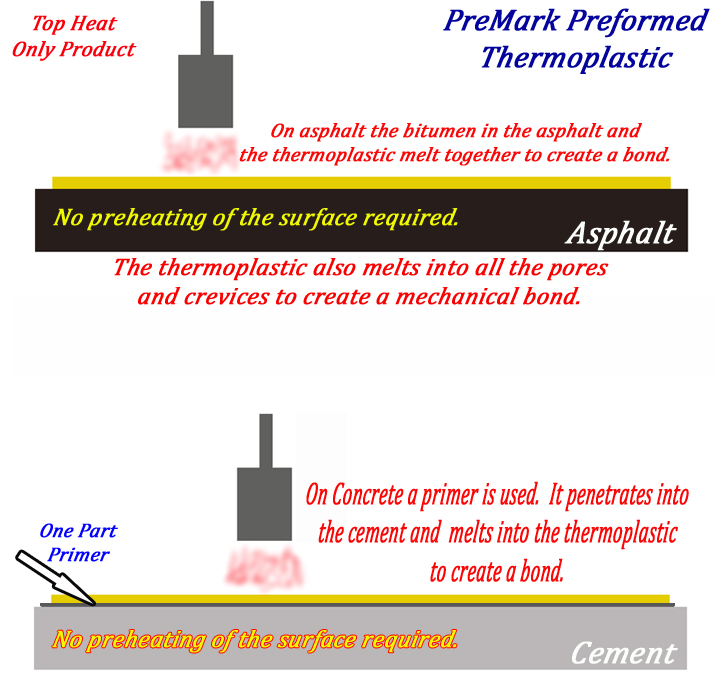

PreMark is a top heat only product meaning that it is not necessary to preheat the surface to a predetermined temperature to install the product. Instead, you simply warm the surface to dry it, lay down your pieces and heat from the top. When it cools it is ready for traffic. With the PreMark product you can lay out all your pieces at one time and then apply heat. This makes applying the material easier when doing long runs.

Premark on Asphalt

On asphalt, Premark becomes a hot liquid when heated to around 300 degrees. Since the bitumen in asphalt has a similar melt point the two materials tend to melt together. Premark also conforms to every nook and crevice and creates a mechanical bond as well. (see diagram above)

Premark on Concrete or Cement

On cement a primer is used first. The primer is made up of an acrylic resin in a solvent carrier. When applied to porous cement it penetrates the surface and carries the acrylic with it. It dries quickly and leaves a layer of acrylic on both the surface and beneath the surface. Then the Premark is positioned and heated just like it would be on asphalt. The hot thermoplastic melts together with the acrylic to form a bond similar to the one you would get with the bitumen in asphalt. Additionally, the material fills all pores and crevices and creates a mechanical bond as well.

Note – Thermoplastic does not perform well on smooth, non porous concrete. To test, put a teaspoon of water on the surface. If it soaks in the thermoplastic should bond. If not it needs to be ground or scarified so that it is porous.

HOT TAPE Preformed Thermoplastic

Hot Tape is a preheat product meaning that it is necessary to preheat the surface to a predetermined temperature to install the product. This temperature is 300 degrees. The main feature of this product is that no primer is needed on cement or concrete. To apply you simply heat the surface to 300 degrees, lay down your pieces and continue to heat from the top until the material is melted. Then let it cool. With this product you would apply the material in stages since it is not possible to heat the entire area at one time.

On asphalt, Hot Tape becomes a hot liquid when heated to around 300 degrees. With this product the preheated asphalt provides the initial heat that begins to melt the thermoplastic from the bottom up. Then heat is applied to the top to finish out the melting process. Since the bitumen in asphalt has a similar melt point the two materials tend to melt together. Hot Tape also conforms to every nook and crevice and creates a mechanical bond as well. (see diagram above)

On cement or concrete no primer is required for Hot Tape. The application method is the same as with asphalt surfaces. The hot thermoplastic achieves a low viscosity and seeps into the pours and crevices of the concrete or cement surface to create a mechanical bond. An infrared thermometer is used to monitor the temperature. This is especially important on concrete as you do not want to over heat.

Note – Thermoplastic does not perform well on smooth, non porous concrete. To test, put a teaspoon of water on the surface. If it soaks in the thermoplastic should bond. If not it needs to be ground or scarified so that it is porous.

Important – After applying either product it is important to do a chisel test. Simply take a chisel or wide screwdriver and chisel up a small piece of the material from the middle. If you see asphalt on the back of the material you have a good bond. On cement you should see where some of the thermoplastic is still on the cement. If your test is postive then just remelt the test area with your torch. If you do not have a good bond you should heat more until you do.